Industrial Equipment

Remote Monitoring with Real-Time Insights

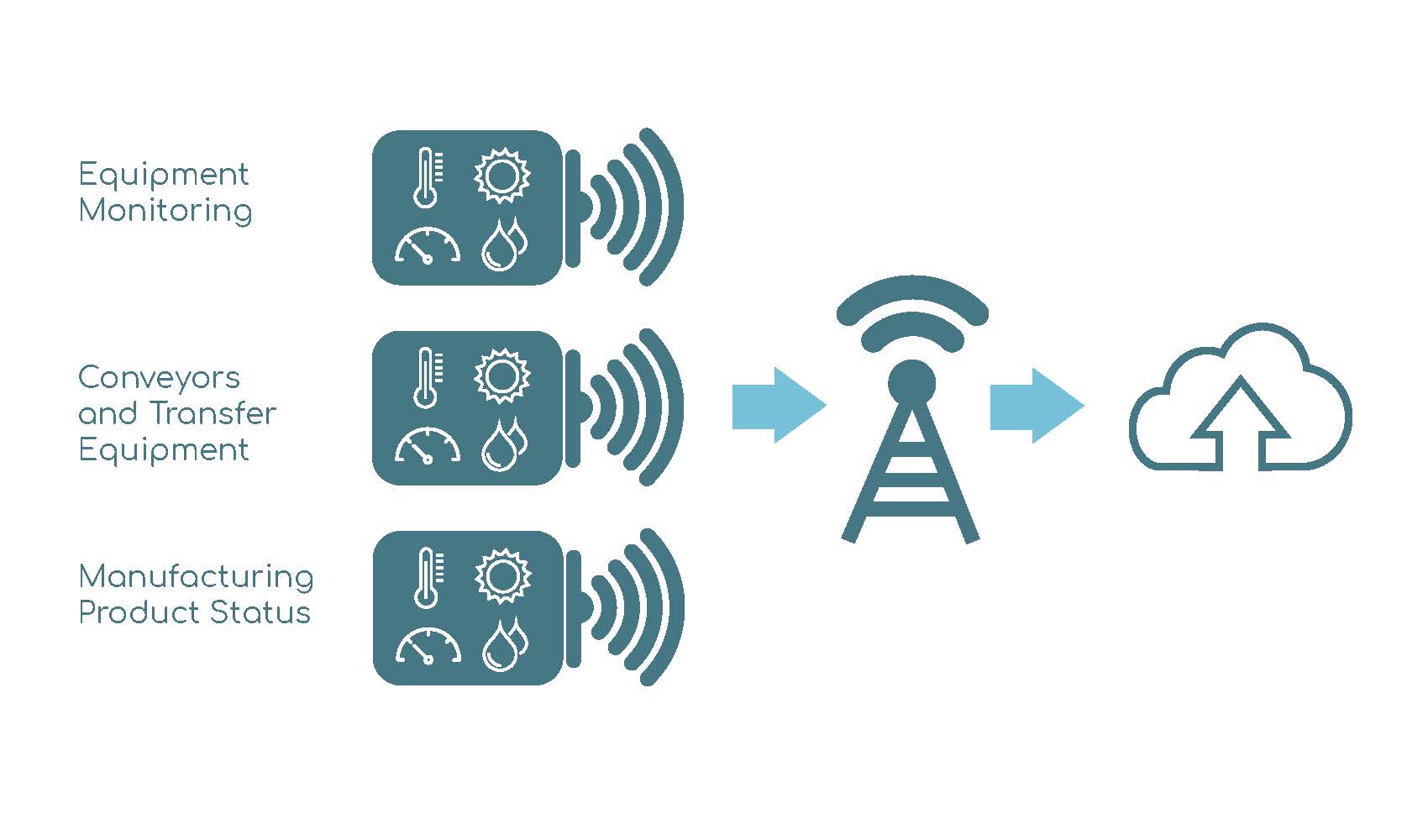

Monitor critical equipment for status looking at vibration, temperature, noise and leaks.

Vibration, temperature, noise and leaks, leak detection and other sensors are installed in the conveyor transfer equipment. Out of limit sensor reading trigger a message to manufacturing service.

Monitor the actual product being manufactured for temperature, noise and vibration. This information can be recorded and sent wirelessly for review and analysis.

This solution solves the complexities of plant infrastructure management. Sensors are installed in key areas that monitor equipment up-time, product delivery counts, replenishment needs and even cleaning cycles. Allowing constant data communication on various parameters. Anomalous sensor data trigger alarms to facilities management. These early warning signals minimize equipment downtime and ensure smooth flow of operations.