Supply Replenishment

Wireless IoT Sensors for On-Demand Replenishment

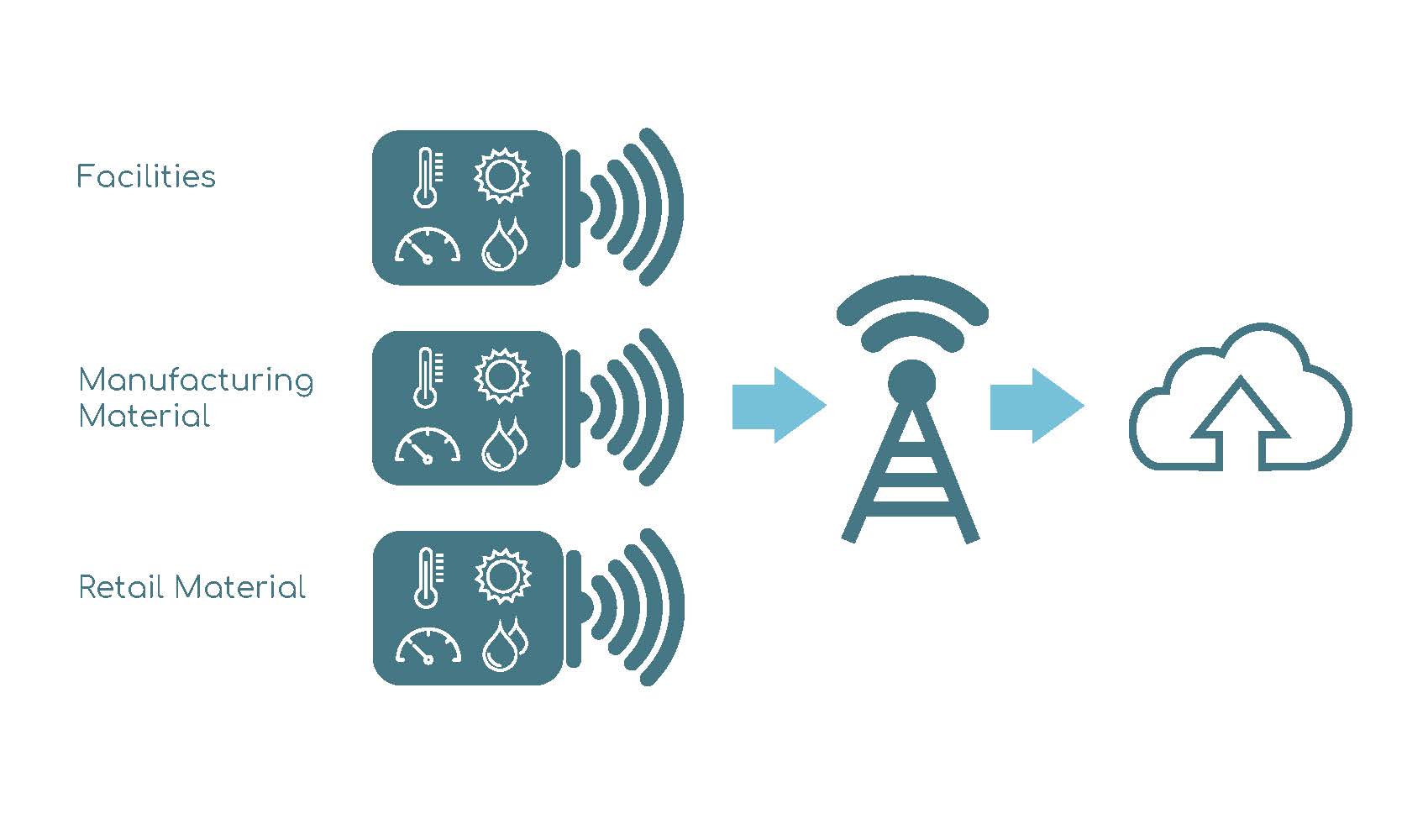

Monitor air quality, temperature and humidity. Additionally, sensors can send information on usage, maintenance status and material replacement status.

Sensors are equipped to monitor material usage and inventory as well as air quality, temperature and humidity related to storage.

Ensure the material and inventory you need for retail operations are available. Additionally, sensors can monitor air quality, temperature and humidity related to storage.

This solution gives you the ability to remotely monitor product quantities at the customer site, which is critical to the on-time delivery of consumable materials. From simply counting dispensing cycles to measuring liquid product volumes and flows, EP Connect sensors can give suppliers real-time data on product quantities at the customer’s point of delivery. This helps businesses coordinate truck runs and product delivery to customers that cannot afford to “run out”. All this can be done outside of existing corporate data information systems over secure cellular data communications.